What kind of foam are you?

Over at All Hazards Contemplations, we're discussing some similarities between firefighting foam and fire officer characteristics.

Firefighting foam has been around for a long time. The Navy, ARFF firefighters, and the petrochemical industry have used Class B foams for decades. When used properly, foam does a good job of extinguishing fire types for which water is not an efficient extinguishing media. Foam can be used on Class A fires, Class B fires, and for hazmat vapor suppression.

Different foams have different characteristics, are applied differently, and do different things. It may surprise you, but fire officers share several of those same features and characteristics. So, let’s think about the characteristics of different foams and apply them to fire officers.

Class A Foam

Class A foams are designed for one thing – fighting structural or woodland fires where the fuels are solid and have no special hazards. Class A foam does an excellent job of sealing air away from fuels and often result in less fire damage to a structure. Class A foams are very efficient at one thing, but they are a one-trick pony. Class A foams are useful as wildland fire barricades or for direct structural fire attack. However, Class A foams don’t produce much steam, so they are very ineffective when indirect fire attack is required, as in an attic fire.

Are you a Class A fire officer? Are you very good at one thing, but very ineffective at the other dimensions that make up your job? Do you perceive your job duties as “We just fight fires”? Are you uncomfortable with any emergency that doesn’t have smoke and flame showing?

CAFS

CAFS is Class A foam that has air bubbles mechanically added at the pump so that the hoseline is pumping finished foam rather than foam solution. It makes the hoselines lightweight and easy to handle. It also makes the hoselines much easier to kink and completely shut off the foam flow than either water or Class A foam lines. Class A foam is high maintenance – it requires a compressed air pump in addition to the water pump.

Are you a CAFS officer? Are you light and frothy, without much substance? Do you seek the easy way to do things without considering that by making some things easier, you may be keeping the job from getting done at all some of the time? Do you require twice the motivation to work as other fire officers? Do you make others chase your “kinks” or otherwise add to others work because of how you do your work?

Protein-Based Foam

Protein Foams are designed for Class B liquid fires. They are old school, having been around since World War II. Protein foams are made from either animal blood and byproducts, from soybeans, or from a combination of both. They may have fluorine added to increase shelf life, but the fluorine adds environmental toxicity to the foam.

Are you a Protein-Based fire officer? Are you old school? Does something have to die to get you to work properly? Do you, like soybeans, create a lot of gas? Like flourine, are you toxic to the work environment? Do you have a long shelf life? Have you changed how you do things, but not enough, despite getting the job done?

AFFF Foam

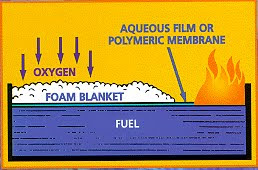

AFFF is a Class B foam that creates a vapor suppressing film between the foam bubbles and the fuel surface. It is very effective on spill fires. It is good to great at sealing flammable vapors into liquid fuel spills. The AFFF film is slick and oily. Applying other Class B foams atop AFFF usually results in the other foam sliding away due to the slickness in the AFFF. AFFF is good for suppressing polar solvent (alcohol) fires, but it requires twice as much concentration (6%) for this application as the normal (3%) application rate needed for hydrocarbon spill fires.

Are you an AFFF officer? Do you suppress anything that rises from below you? Do you do a good job, but have a slick and oily finish? Do other fire officers not mix well with you?

AR-AFFF Foam

AR-AFFF is a new foam type that is similar to the older AFFF, but with several important differences. AR-AFFF is around 50% more expensive than standard AFFF. However, it is applied at 1% to hydrocarbon spill fires and 3% to polar solvent fires, so a given quantity of AR-AFFF will suppress three times as much fire as an equal quantity of standard AFFF. This results in an actual decrease in cost-per-gallon of the foam concentrate. Typical AR-AFFF is completely biodegradable, and is manufactured without the fluorine additives common to AFFF and protein foams. That makes it a much better choice for fighting both hydrocarbon and polar solvent fires. Additionally, AR-AFFF can be mixed at 0.5% and used as Class A foam for both wildland and structural firefighting applications, making it the most flexible foam currently available?

Are you an AR-AFFF officer? Are you flexible? Can you adjust your approach to adapt to different problems and challenges? Are you friendly to your work environment instead of using effective short-term solutions that leave long-term toxicity in your environment? Are you effective in handling a variety of emergencies rather than just being good at one thing? Can you adjust your intensity and concentration to fit with changes in your work environment?

High Expansion Foam

High Expansion Foam is designed to fill up confined spaces and exclude fire. It does not perform well in exposed positions, because its high expansion ratio makes it light, fluffy, and easy to blow away in a light wind. High expansion foam applications are so limited that most public fire departments don’t even carry it. High expansion foams require special application devices. They also require a lot more effort than conventional foams in order to be effective.

Are you a High Expansion officer? Do you require special treatment to be effective? Does it require additional effort by someone else to make you get the job done? Are you light and fluffy, without substance, and easily blown away by the winds of change? Are you comfortable only within narrowly-defined limits?

Hazmat Foam (vapor suppression foams)

Hazmat Foams are designed to suppress vapors from liquid hazmat spills. They are usually not effective for firefighting in Class A, Class B, or polar solvent fires. They are very, very good for one thing – preventing vapors from rising up from below. In this respect, hazmat foams are even more specialized and limited than is traditional AFFF. Hazmat foams are very effective not only at keeping vapors from entering the environment, but they are effective at keeping the environment out of the hazmat spill.

Are you a Hazmat Foam officer? Are you useless at firefighting? Do you suppress the idea vapors rising from your subordinates into the general environment? Do you work harder at keeping the environment out of your firehouse than you work at being an effective leader?

In conclusion, all firefighting and hazmat foams have their place. Good fire departments have access to all kinds of foam in order to handle a variety of fire and hazmat incidents with the best possible solution. However, not all “Foam Officer” types are good for either the fire department or for the firefighters. The best fire officers have AR-AFFF characteristics; they are flexible, they are good for several different problem types, they can suppress problems when needed, they are cost-effective, and while seeming more expensive on the surface, they actually save the department time, money, and effort in the long run.

And remember, even good fire officers, like good foam blankets are not perfect. Sometimes problems break through the fire officer's ability to handle them, just as the fire can break through the foam blanket.

Add a Comment

-

Comment by Ben Waller on March 6, 2010 at 9:22am

-

John, that's an excellent point, and thanks for adding it. Now if I could just find a cool picture of some water...

-

Comment by John Crabbe on February 2, 2010 at 11:37pm

-

Since I'm not an officer, I will have to go with water, because not a damn one of these foams is good without it. A good officer has good firefighters.

-

Comment by Ben Waller on February 1, 2010 at 6:07pm

-

No problem, Frederick. It is important enough that discussing it further is a good thing, and expected.

-

Comment by Mike Schlags (Captain Busy) Retd on January 31, 2010 at 4:12pm

-

I guess, from your analogies I would have to be an AR-AFFF (Alcohol Resistant Aqueous Film Forming Foam) kind of an officer... However, considering that I really don't drink much I suppose you can say that I am able to successfully resist alcohol... which would make me alcohol resistive, right?

CBz

-

Comment by blair4630 on January 30, 2010 at 7:03pm

-

Well, I am not, and have no aspiration to be, a line officer. But I have to say, it's a good analogy, and a pretty damn good review of foam applications too!

-

Comment by Ben Waller on January 30, 2010 at 6:38pm

-

Ted, my goal is to get people to say to themselves "I've never thought of it that way." If I can do that even once per day, I've had a successful day.

Specialty Websites

Find Members Fast

Firefighting Videos

© 2026 Created by Firefighter Nation WebChief.

Powered by

![]()

Badges | Contact Firefighter Nation | Privacy Policy | Terms of Service

You need to be a member of My Firefighter Nation to add comments!

Join My Firefighter Nation